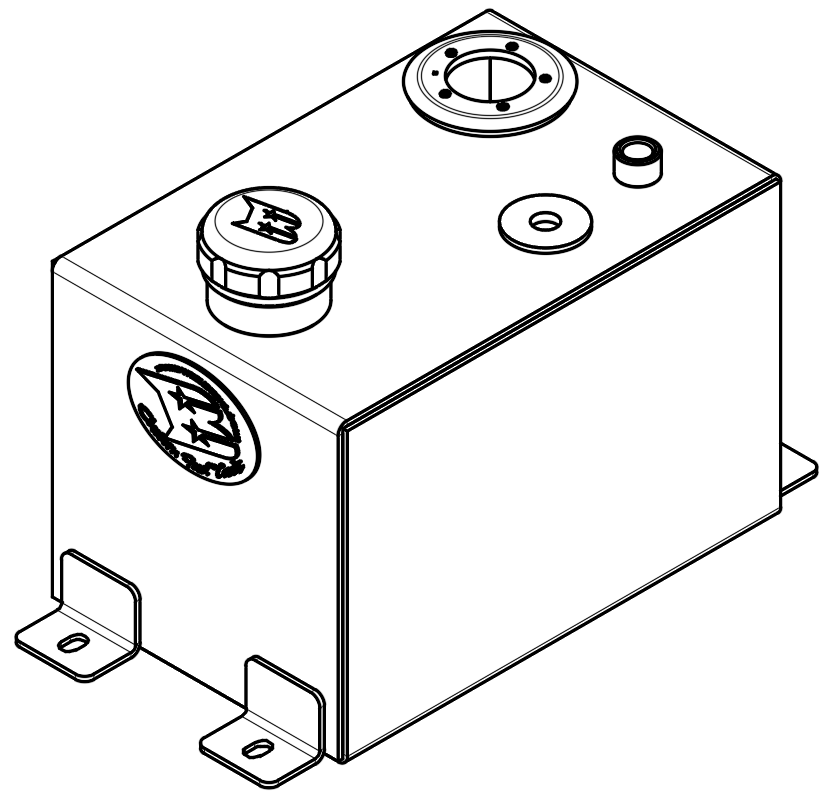

Aluminum Tanks custom built to your drawings or 3D Model. That's our specialty!

Our most common built products for other companies like you are:

-

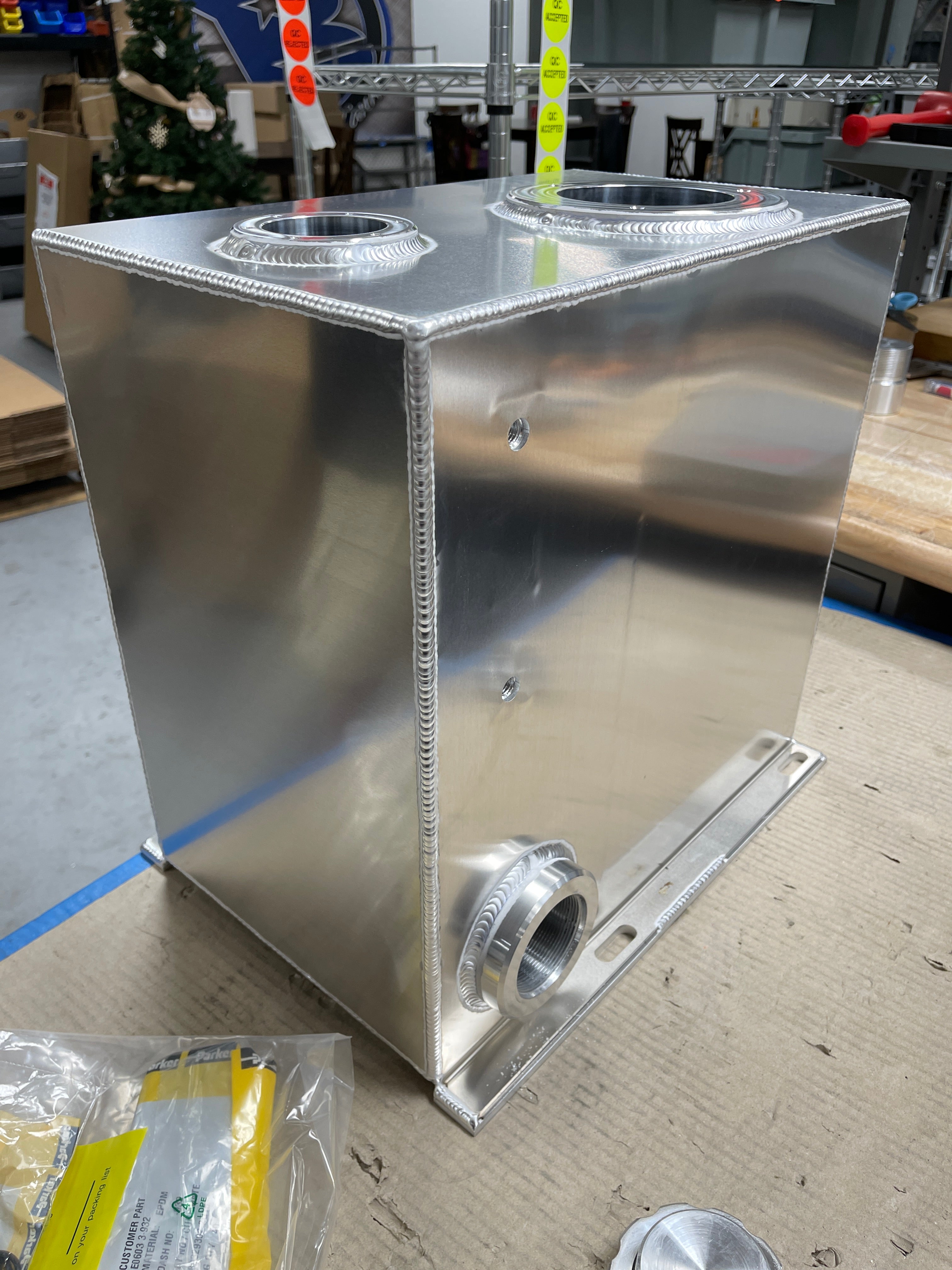

Fuel Tanks

Aluminum tanks are a perfect solution for many applications. when built correctly they are strong, lightweight, non permeable and will not deform from sunlight.

-

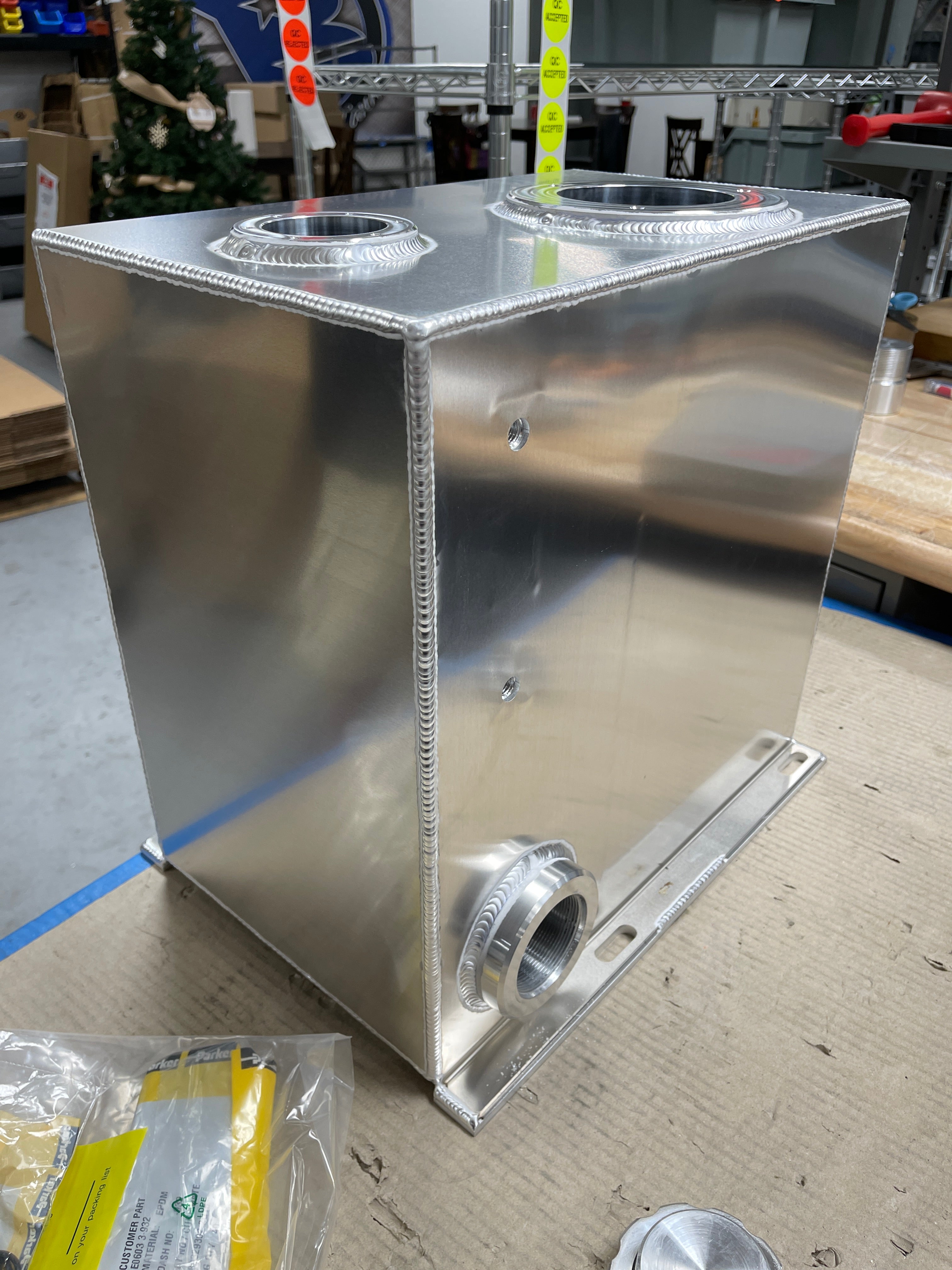

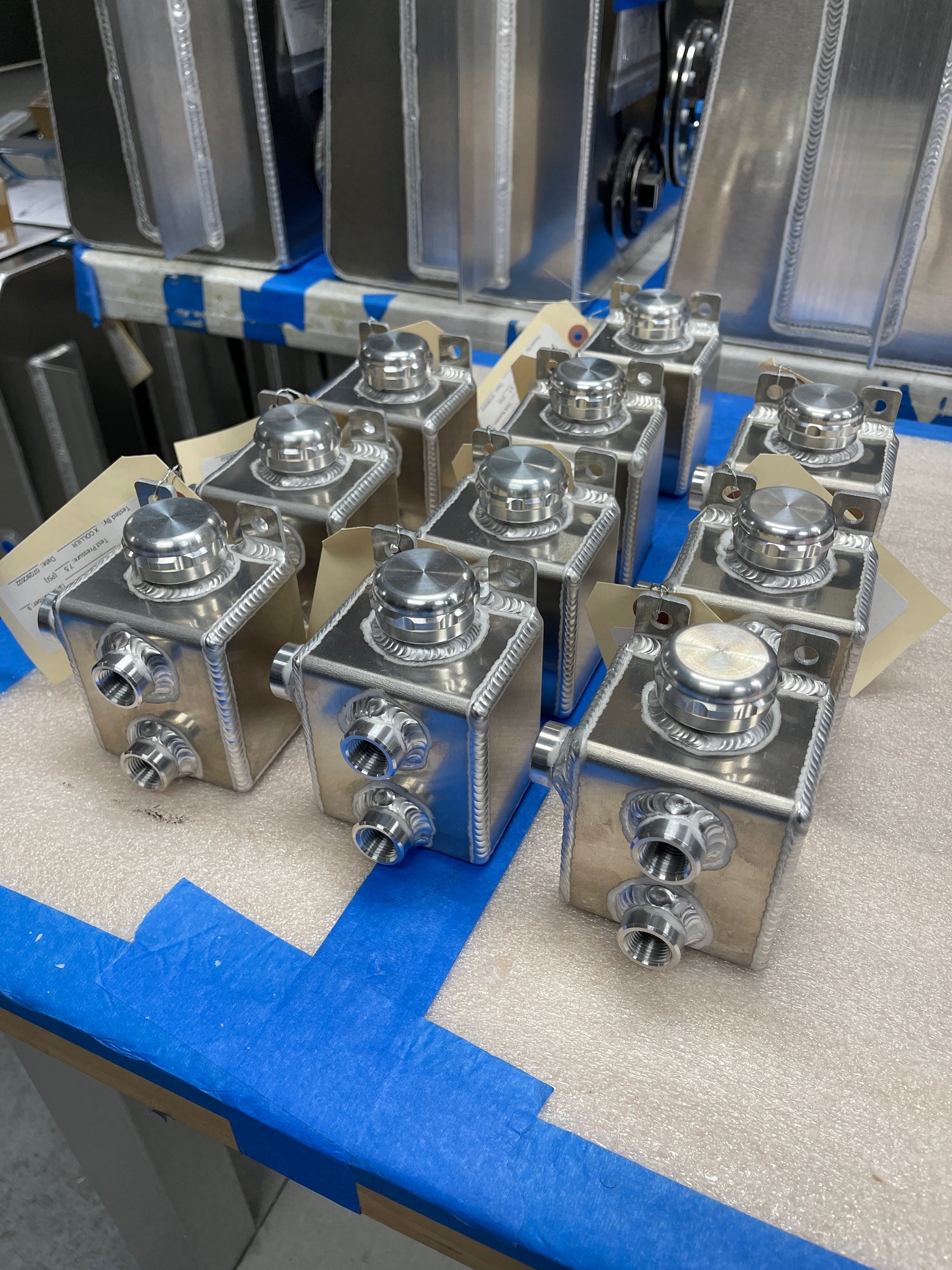

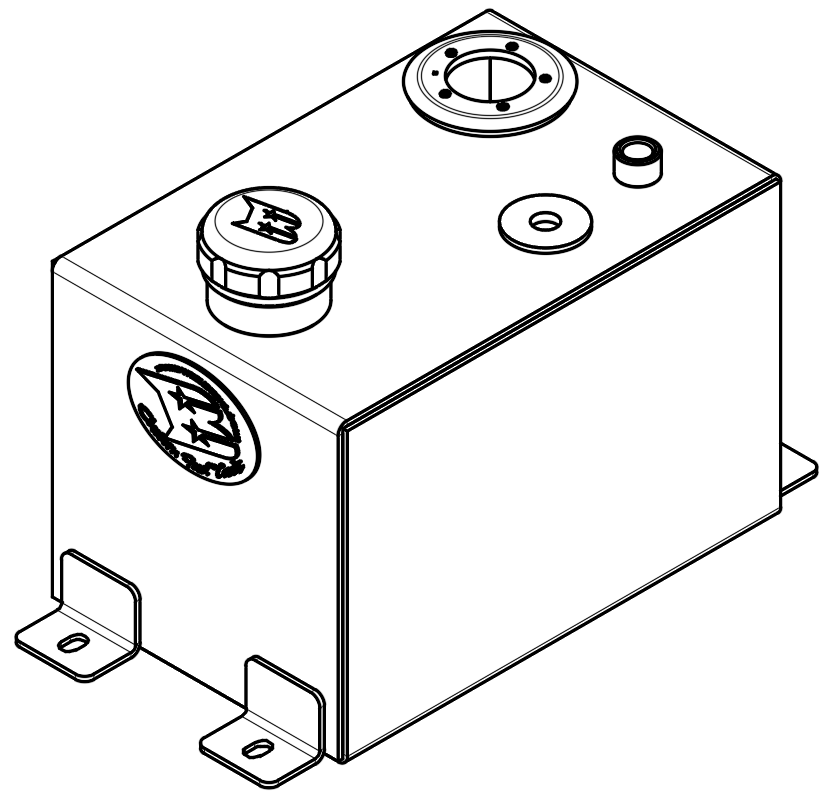

Coolant / Water Tanks

Coolant Tanks can be built to pretty much any dimension with integrated mounting tabs, custom fittings, fills, dipsticks or pressure ratings are all possible.

-

Hydraulic Tanks

Don't buy an off the shelf product just to modify it in-house. Send us your drawings, lets build it together

-

Tool Boxes / Cabinets

we bring our high end welding processes and excellent surface finish experience to industrial tool boxes.

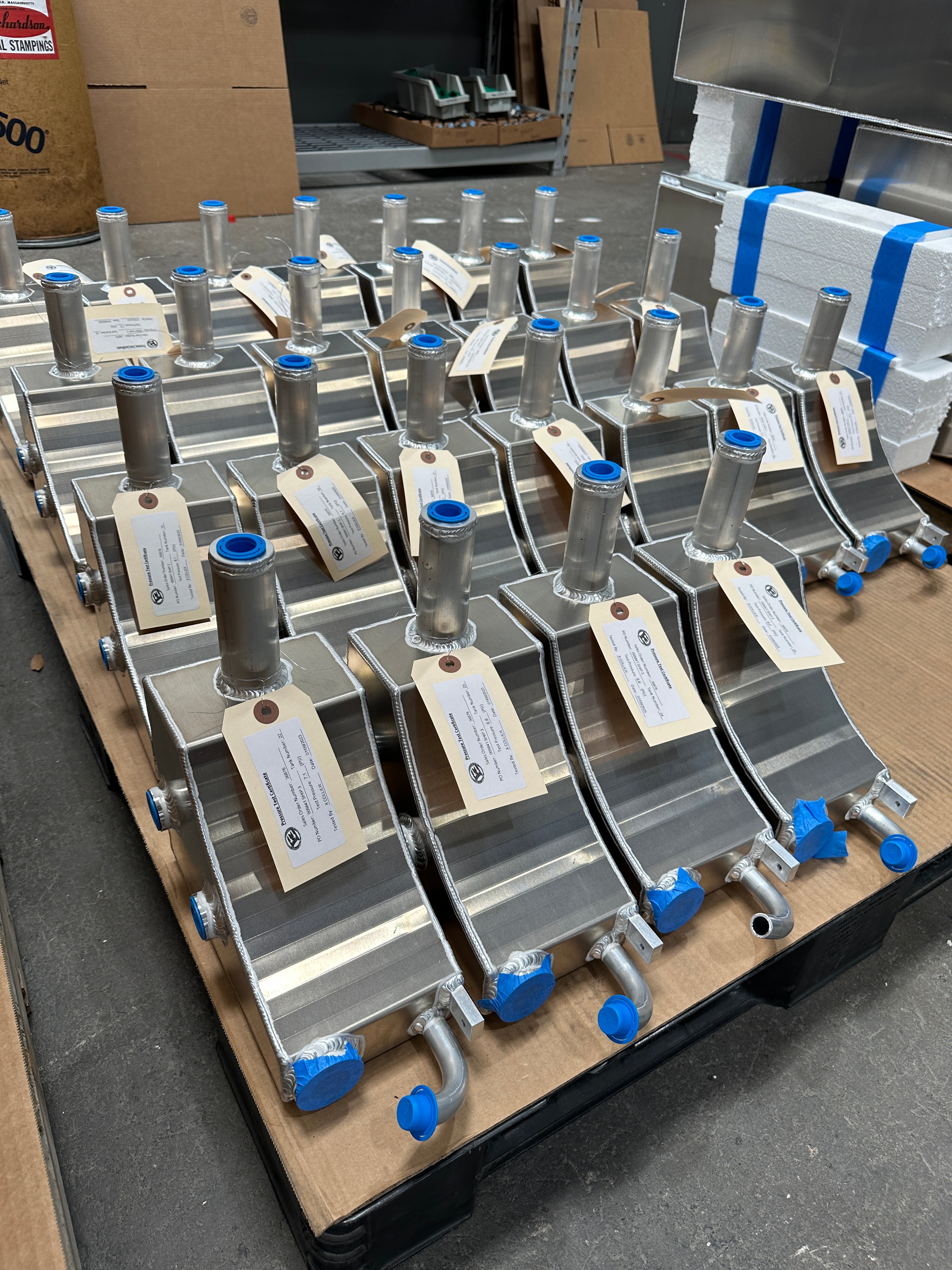

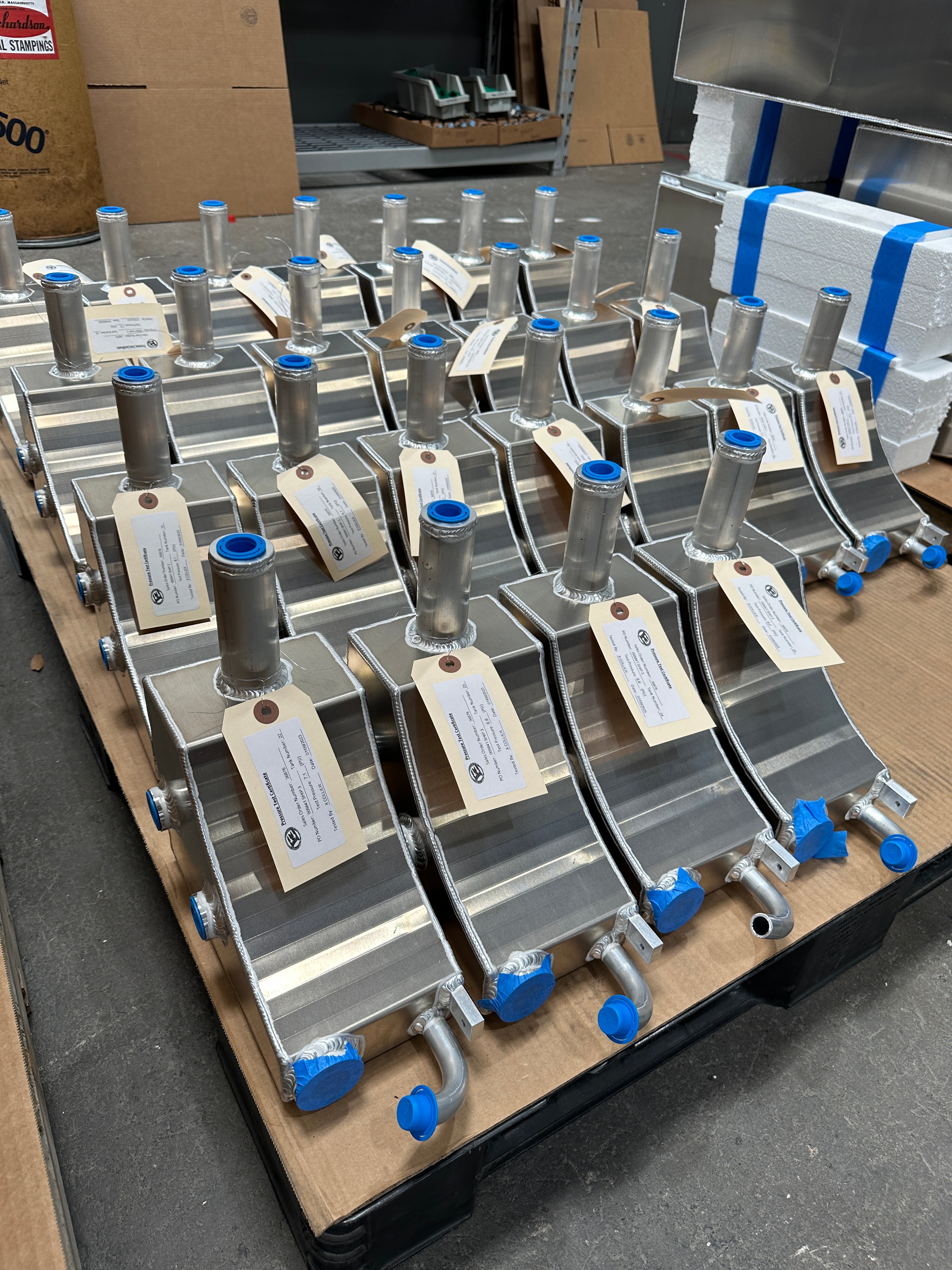

QTY 10 Tank Minimums in most cases

We DO NOT build ONE-OFF custom tanks. However, we do build prototypes and first articles for all production customers.

After prototyping and with your approval we can go directly into production. Our Typical Production runs span from 10 PCS to 500 pcs per shipment.

Do you match our typical customer?

Our Custom Tank customers meet the following criteria.

- Well established business who values quality construction

- Has capabilities to design and communicate fabrication related needs efficiently

- Willing to purchase in MOQ of 10 pcs after Prototyping

- Willing to pay when services rendered. N30 Accounts can be established once weekly / Monthly production orders are issued.

What We Bring To The Table

-

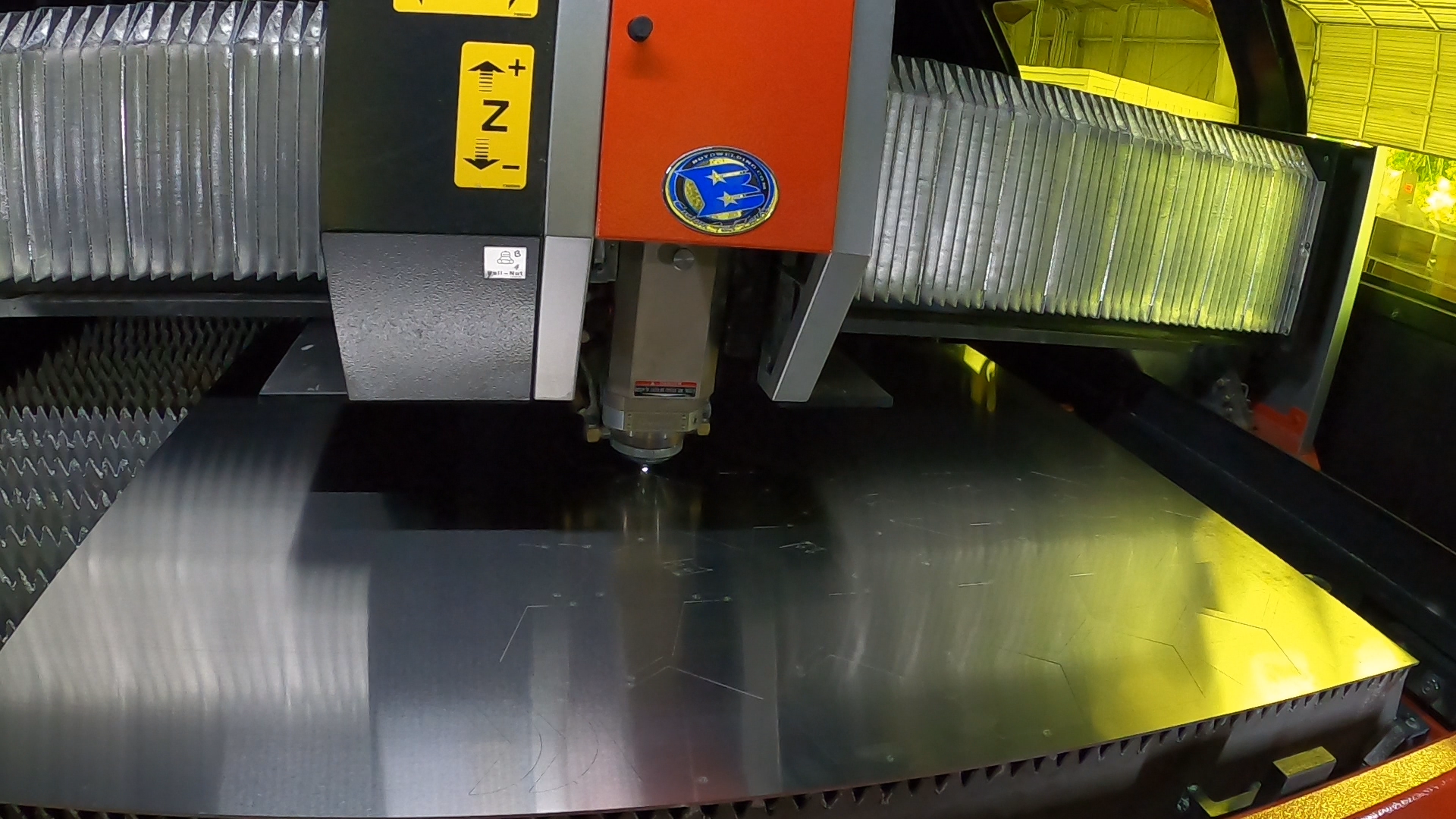

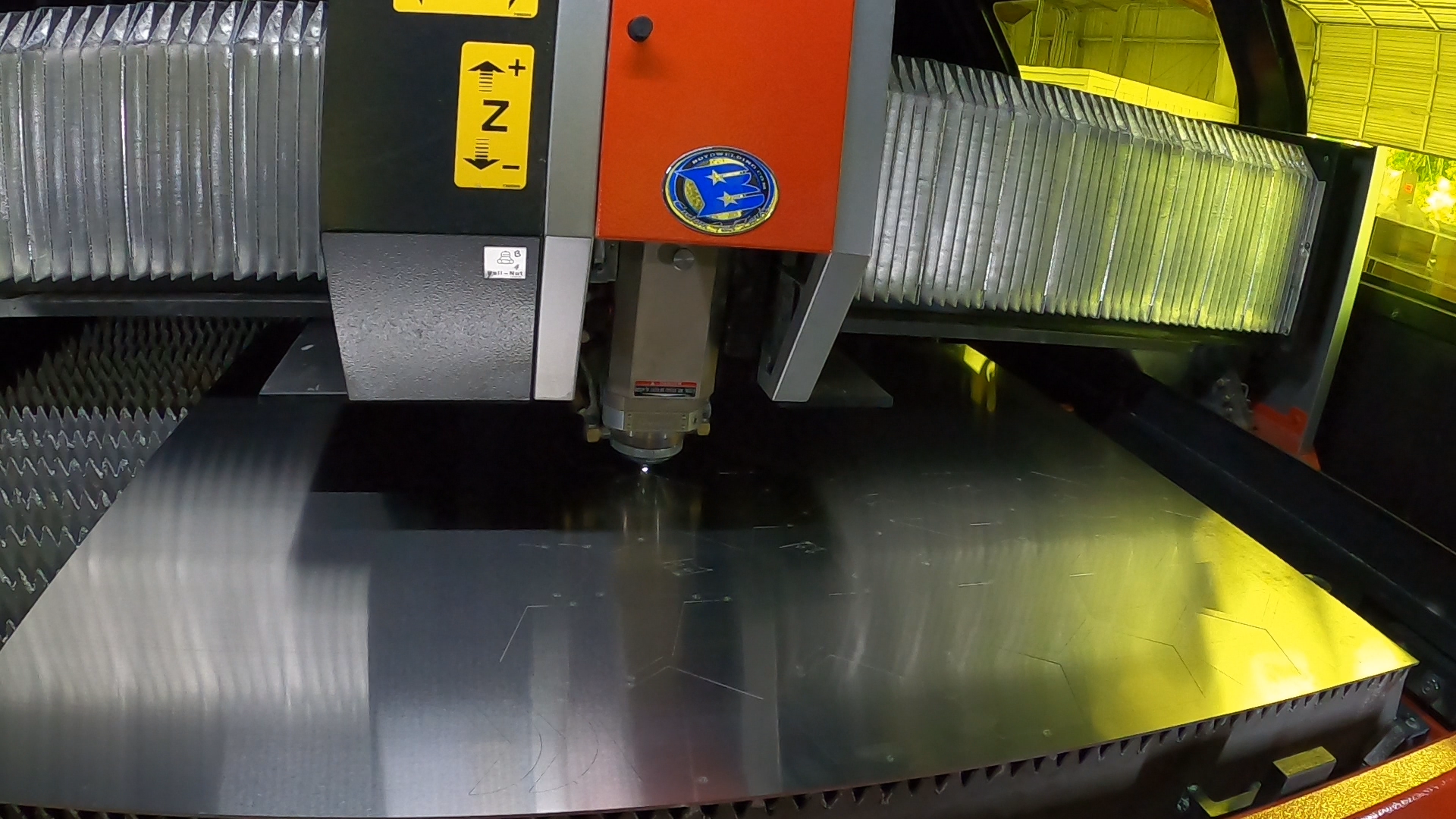

CAD / CAM Driven Fabrication and Machining

We have a 4K Fiber Laser, 6 Axis press brakes, CNC Lathes & Mills to meet any fabrication need. We even generate our own Nitrogen in-house for clean weld ready edges

-

AWS D1.2 Certified Aluminum Welding

High end aluminum welding is in our core. Our processess and internal training allow the best welders in the industry to perform at a very high level every day.

-

100% Leak Testing and inspection

Every tank we build undergoes a documented leak tesing process. Average tanks are tested underwater between 5-8 PSI, reviewed for a period of time then serial numbered individually.

-

Consistent and Dependable

Since we manufacture most of the parts used in-house we have the flexibility to make custom parts or maintain supply when others cannot ensuring our tanks are delivered on-time when we say it will.

Did we Match? If so, lets get started.

-

STEP 1 - Gather your Information

Success is in the details. Utilize our website to gather SKU#'s of the fittings, caps, necks you would like us to use. Don't Worry if you dont see something though, We will make it if needed.

-

STEP 2 - Prepare Your Drawings

We accept .PDF .DWG. STEP . IGS and Solidworks or Fusion 360 Native files. If you are modifying one of our tanks you can redline of our published drawings